Adsorption heat pump

Contact

- ProductsWater Vapor Adsorbent chiller/heater

- Manufacturing companyFahrenheit (Germany)

- Relation

- Low temperature heat use

Adsorption Heat Pump Chiller (or Heater)

Applications

Adsorption Heat Pump for Air-Conditionings and Cooling Processes

Applied Locations

- Steelmaking Plants

- Cast Incinerator Plants

- Chemical Plants

- Foods Factories

- Hot Springs

- Cogeneration Plants

Adsorption Heat Pump (AdHP) Chiller

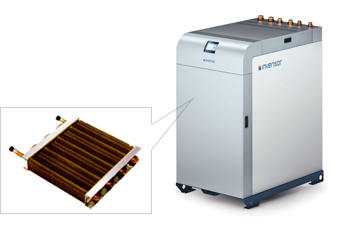

Manufactured by Fahrenheit utilizing coated heat exchanger inside

Fahrenheit's Adsorption Heat Pump (AdHP) Chiller eCoo10 - 10KW (36,000 BTU/hr) cooling capacity (pdf758kB) as displayed. The chiller utilizes hot water generated by CHP (Combination of Heat and Power) using natural gas. Co-generation system can change to "TRI-GEN" to generate electricity, heat and cool working with AdHP chiller.

FEATURES

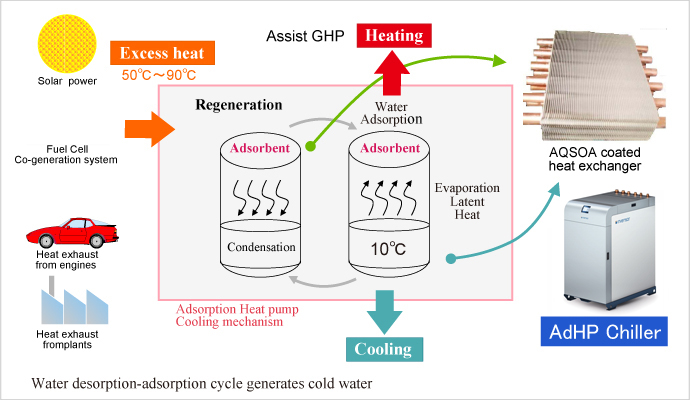

1. THERMAL DRIVEN CHILLER - no electricity is used in chilling mechanism

==> Electrical COP = 10 (10kw cooling capacity from 1 kw electricity - control, pump, recooling unit)

2. No Freon/Lithium Bromide/Ammonia is used - WATER is cooling media

3. No compressor is used - VERY QUIET

4. By using 65 degree C (149 degree F) hot water, 10-15 degree C (50- 59 degree F) chilled water can be produced.

5. Best fit to Solar hot water, biomass plant, geothermal, CHP (Combined Heat and Power) and other waste heat source

For details, please inquire from this button.

Principle of Adsorption heat pump

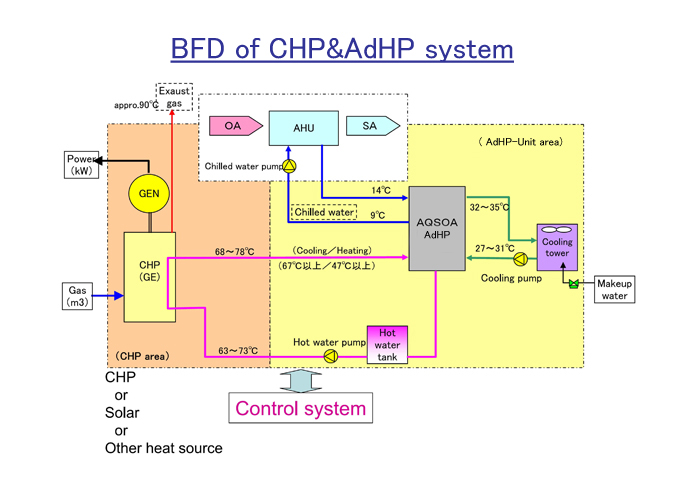

Block Flow Diagram of AdHP chiller with CHP (Combined Heat and Power)

Please visit the links below to view details

> Fahrenheit (Munich, Germany) Adsorption Heat Pump (AdHP) Chiller

Fahrenheit eCoo series Lineup - COP